Little engine that could

12-second, 28+ MPG 2.2L Omni streetfreaker built with factory parts. And hold the nitrous please.

Twelve second cars. Yeah, your uncle Herbert's got a 454 Chevy that once ran in the twelves, after he towed it to the track, and bolted on a set of 11-inch slicks. He only had $7,000 in the motor, too. Your buddy down the block had a Buick Grand National that ran in the twelves, but he bought head baskets by the case and kept spare transmissions in his glove compartment. He finally got so many speeding tickets that he had to sell the car to pay for 'em.

Then again, virtually everyone reading this magazine has, or knows someone who has, a Mopar that runs twelves. It's not that hard, really. Consider this, though: when was the last time you say a diminutive little 135 cubic inch econobox 4-door run twelves, get 28-plus MPG, corner at 0.9Gs, and stop on a dime and give you six cents change? Still not impressed? Suppose we told you this car had a stock camshaft, stock compression, and was built using factory parts exclusively? This is virtually the automotive equivalent of having your chocolate cheesecake and eating it, too.

We saw this car run, er, make that Run, with a capital R, at the '86 Mopar Nationals. It runs fast, pulls hard, and generally, does everything a good musclecar does. Except...it does it on pump gas, starts on the first turn of the key, and has ice cold air conditioning to boot! Then, too, as we said, it goes 28+ miles on 4 quarts of gas, and looks like a total stocker! Now, if it seems we're impressed, it's 'cause, oh yeah, we are! The personal toy, er actually daily commuter vehicle of Chrysler Engineer Dave Zelkowski, is Fun, with a capital F.

Dave and his diminutive little L-body have become something of living legends. After cleaning the class clocks at the Computer Car Nationals in '89, the pocket rocket was prominently featured in both Hot Rod and Turbo magazines. Both those publications told us how expeditiously Dave's car gets down that quarter-mile strip of tarmac, but teased us with little more than rudimentary information about the mechanical goodies lurking beneath its little red bonnet. Luckily for us, Dave has generously agreed to share with us all his secrets. Actually, as we mentioned, there are precious few trick parts in Dave's car, just liberal doses of sound engineering and a bountiful bevy of factory parts.

It was at about the time that Dave had attained the status of "instant celebrity" that Dave, myself, and longtime friend Joe Leonard began discussing an entry for the 1990 Cannonball One-Lap of America, It was quickly decided that an Omni like Dave's could be competitive, which it surely was (see p. 36 Mopar Action, Dec. 1990), but it was just as quickly decided (by Dave!) that his original, one-of-a-few red rocket wasn't up for grabs. So, Dave took the "easy" (?) way out, and built a clone out of two wreaked GLHs. (Like, warm up the chain saw, Vern!) That's how the black car came to be.

Starting PointThe base car for these buildups were stock Turbo I 4-dr. Omni GLHs. You could just as easily use a Shelby Charger, although you'd be burdening yourself with 100-pound weight increase (and no headroom for 6-footers). You could really start with any 5-speed 2.2L L-body, although you'd want to bring the car up to GLH/Shelby specs first: brakes, suspension, steering rack (fast ratio), hubs, wheels, and tires are a few of the obvious differences.

Engine-Bottom EndThe short block Dave uses is a 100% stock '87-88 Turbo II piece, unmodified. Oiling system, crank, rods, pistons, rings, bearings, etc. are run literally right out of the box, although some early '87 motors had rods that were suspect and should probably be visually inspected, or, better still, magnafluxed. The only "trick" item here is the lubricant: Mobil 1 synthetic oil is used exclusively. This would seem to be sensible for any turbo motor.

The 1989 Turbo II short blocks can be utilized as well, if so, you'll also need the '89 version oil pan, pickup, and camshaft drive system.

Cylinder Head and ValvesDave's minirocket was initially assembled several years ago, before the advent of Mopar Performance's ready-to-go cylinder heads. Hence, Dave used the best head available at the time, which was the 1985 "G" casting. Modified Toyota valves, measuring 44mm on the intake side and 36.15 on the exhaust, were utilized, along with like-sized seats. One reason that the factory never went this large on production heads is the fact that when valves of this size are fitted, the seats run into each other, and the gap of headcasting material normally present between the seats vanishes. To date, though, Dave has had no problems with this setup, and hasn't heard any other negative feedback.

The "G" heads also required a quick pass under the surface grinder to bring the compression ratio back up to the stock ratio. This was required as the Turbo II short blocks weren't released until 1987 and were therefore designed for use with the newer, small-chamber, high-swirl head castings. The cut Dave had to make to this head then required a modified timing belt tensioning arrangement and a shorter belt. Now that Mopar Performance has released the ready-to-go head, based on the '86-up casting, none of these mechanical gymnastics are required. You simply ask the man for one of part number P4529353 and bolt it on.

Be certain that you use a Turbo II head gasket, as the cooling passages are different than the "I" motor.

The camshaft, followers, and retainers are all stock '84-'87 Turbo pieces (flat follower). The cam is installed at 114 degrees c.I. Note that '87 cams are the same, whether for Turbo I or Turbo II. The '88-up roller cams offer less duration and overlap for better idle quality and emissions, and should therefore be avoided in a performance build-up.

Valve springs are Mopar Performance race, part number 4286540.

Intake and Turbo

Intake and TurboThe intake manifold is a stock Turbo II piece, carefully port-matched where the two halves mate. At the throttle body mounting pad, a die grinder is used to open up the throat to match the output of a 52mm throttle body from a 1987 3.0L Mitsubishi V-6 mini-van motor. Watch this, as the later 6s used a smaller, more restrictive, 46mm throttle body.

For a turbocharger, Dave chose the Mopar Performance "plus" unit, which features a high-A/R ratio. The intercooler, radiator, and associated plumbing are basically stock Shelby GLH-S items.

The air cleaner should have the zip tube cut off and an aluminum plate fabricated (to close off the hole) pop-riveted into place and sealed with RTV silicone sealer. Both of the hoses shown in the parts list will have to be shortened because of the shorter engine bay. Recent experimenting has shown that a '91 Spirit R/T hose is a perfect fit. The hoses do not have the ribbing like the stock pre-'89 Turbo II hoses. On Dave's car, the swap to the unribbed hoses were worth an incredible 3 tenths and 3MPH in the 1/4 mile. The air cleaner is mounted further rearward than in a Daytona so the hose from the power module will be in line with the air cleaner. Do not run without the inlet hose, the warmer underhood air will slow the car down.

ExhaustHere's the one place where conventional hot rodding came into play. Dave had a custom exhaust system fabricated out of 2-1/2 inch stainless tubing, and, on the red car, utilized a Flowmaster muffler. Despite the diminutive size of the car and the rather large plumbing, everything fit quite nicely.

Since the black car was to be used for long-distance cruising, a quieter, stock-type muffler was fitted.

Drive Train

Drive TrainDave knew the standard transaxle would be the weak link in the car, so he didn't mess around. He did it right the first time, installing a Getrag-cogged New Process A-555 transaxle. Until Dave got into the car and started twisting wrenches, nobody knew if it'd fit an Omni; remember the A-555 was only "officially" used in the K-based cars such as the Daytona and LeBaron. As luck would have it, the installation wasn't difficult, requiring just a few tricks.

The A-555 bolts in with no interference. The bobble strut bracket on the suspension crossmember needs to be relocated on the crossmember to line up correctly with the A-555 viscous damper. You could conceivably cut off the original one and reweld it in the right spot, but Dave took the easy way out, welding on the new bracket shown on the parts list. He didn't even bother cutting of the stock bracket.

The transaxle itself is 100% stock except for the addition of a Sure-Grip differential from Shelby's now defunct parts operation. As of this writing we're trying to ascertain what's become of Shelby's inventory of these differentials. As soon as we find out, we'll clue you in.

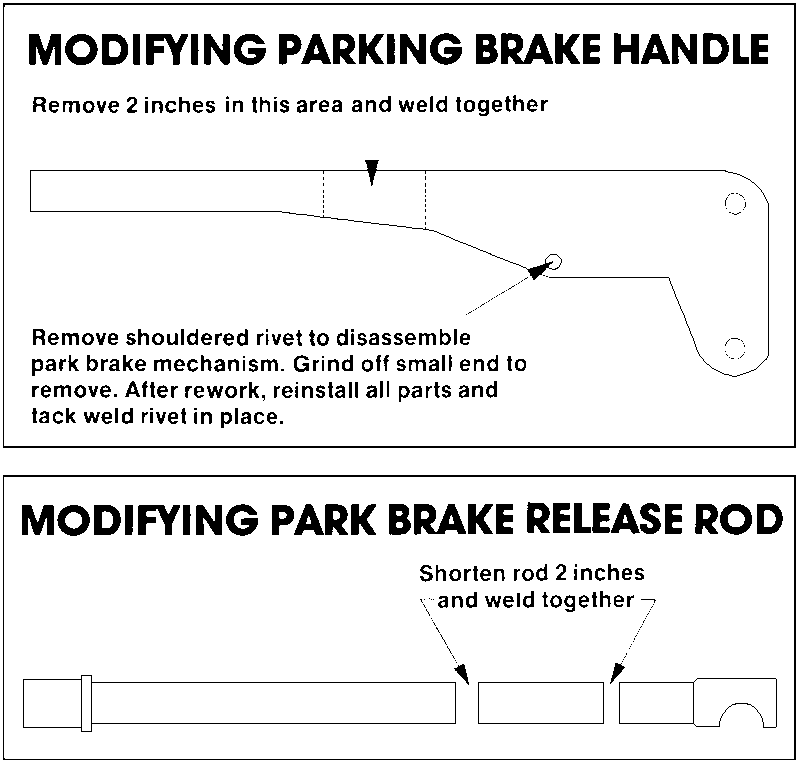

You must modify the parking brake lever and release rod (per the drawing) and reinstall them. The shifter, which is basically a P-car (Shadow) unit, mounts just behind the floor-to-dash console. No cutting of this console is required. Use two of the original shifter mounting holes to fasten the new shifter by drilling the shifter in the appropriate places and making a spacer to compensate for the somewhat different floor pan shape. The shift cables are routed under the storage box (where the cable would be routed if the car had an automatic transmission), one through the center of the storage box bracket and one to the left of it. Each cable will have to go through a separate hole in the floor, being careful to route the cables away from the exhaust system.

The drive shafts are custom-shortened 3.0L minivan (see parts list). Arrow Racing Engines in Detroit will make up the drive shafts to Dave's specs (see drawing), but you must send the bare shafts with no U-joints. The only shaft that will take the abuse of repeated 12-sec. runs are the ones in the parts list.

The outboard U-joint on the stock minivan (3.0L) shaft is adequate to reuse if you buy a junkyard piece. If you can make a deal and buy both the right and left shaft, you can use both joints from the left shaft and you'll have an outer side spare. The shafts Dave runs at the present have stock Daytona Turbo II joints, but his spares have the minivan joints, either are acceptable.

The intermediate drive shaft and bracket are stock '87-up turbo K-platform pieces (Shadow, LeBaron, Daytona, etc.)

| Parts List for Installation of A555 Transmission Into L-Body | |||

| Qty. | Production Part no. | Service Part No. | Description |

| 1 | 4446380 | 4446381 | A555 Transmission |

| 1 | 4295345 | Same | Decal & Ret Assy |

| 1 | 4431264 | Same | Knob |

| 1 | 4431395 | 4431397 | Mech Assy G/Shift |

| 1 | 4446810 | G/Shift Cont Cable - Selector | |

| 1 | 4446878 | Same | G/Shift Cont Cable - Crossover |

| 2 | 6501431 | Same | Clip - RR |

| 1 | 6501332 | Same | Clip - G/Shift Oper LVR - Select |

| 2 | 4269830 | Same | Clip - FRT |

| 3 | 6100296 | Same | Screw - G/Shift Cont Cable MTG MRKT |

| 1 | 4269461 | Same | Stud - G/Shift Oper LVR - Crossover |

| 1 | 6100499 | Same | LK Nut - G/Shift Open LVR Stud Crossover |

| 1 | 4446939 | Same | BRKT - Cable MTG FRT |

| 1 | 6501340 | Same | Stud - G/G Shift Oper LVR - Select |

| 1 | 6100500 | 6500197 | LK Nut - G/Shift Oper LVR Stud - Select |

| 2 | 6100879 | n/a | WA - G/Shift Oper LVR - Select |

| 1 | 4412707 | n/a | BRKT - G/Shift, Console MTG |

| 1 | 4377289 (Paint as reqrd | F333FS8 F333GR8 F333FK1 F333FC5 | Base Assy (Gearshift Cover) Charcoal Red Light Almond Twilight Blue |

| 4 | 0167061 | n/a | Screw - Base Assy to G/Shift |

| 1 | 4377331 | Same | Boot Assy |

| 1 | 5212991 | Int Shaft Yoke | |

| 1 | 4377450 | 4364769 | Damper Assy - Eng Roll (Service No. includes BSHGS.) |

| 1 | 6100525 | Same | Nut - Damper MTG |

| 2 | 4377451 | (Included w/ Damper in service | Bushing - Eng Damper Upper |

| 1 | 6500966 | Same | Bush Ret - Upper |

| 1 | 6500967 | Same | Bush Ret - Lower |

| 1 | 4323000 | Same | BRKT - Weld On, K Member to Roll Damper |

| 2 | 4446981 | n/a | Seal - G/Shift Cable to Floor ('90 MY Part) |

| 1 | 4384702 | Same | Joint - Complete Outer |

| 1 | 4384706 | Same | Boot PKG - Outer |

| 1 | 4505905 | Same | Housing - CV Inner |

| 1 | 4384709 | Same | Tripod PKG - Inner |

| 1 | 4505907 | Same | Boot PKG - Inner |

| 1 | 4384728 | Same | Driveshaft - LT, Modified |

The clutch (pressure plate and disc) is a 100% stock Turbo II unit (230mm). This is generally considered to be the weakest link in the drivetrain, but all aftermarket units Dave has experimented with have been no better. Dave has actually had very few clutch problems.

The '89-up clutches are inferior and to be avoided. This is due to the fact that, starting in '89, non-asbestos friction material was substituted to comply with government regulations. The original '87-'88 clutch is still available from Mopar.

The flywheel is also a stock Turbo II item, and has proven itself raceworthy.

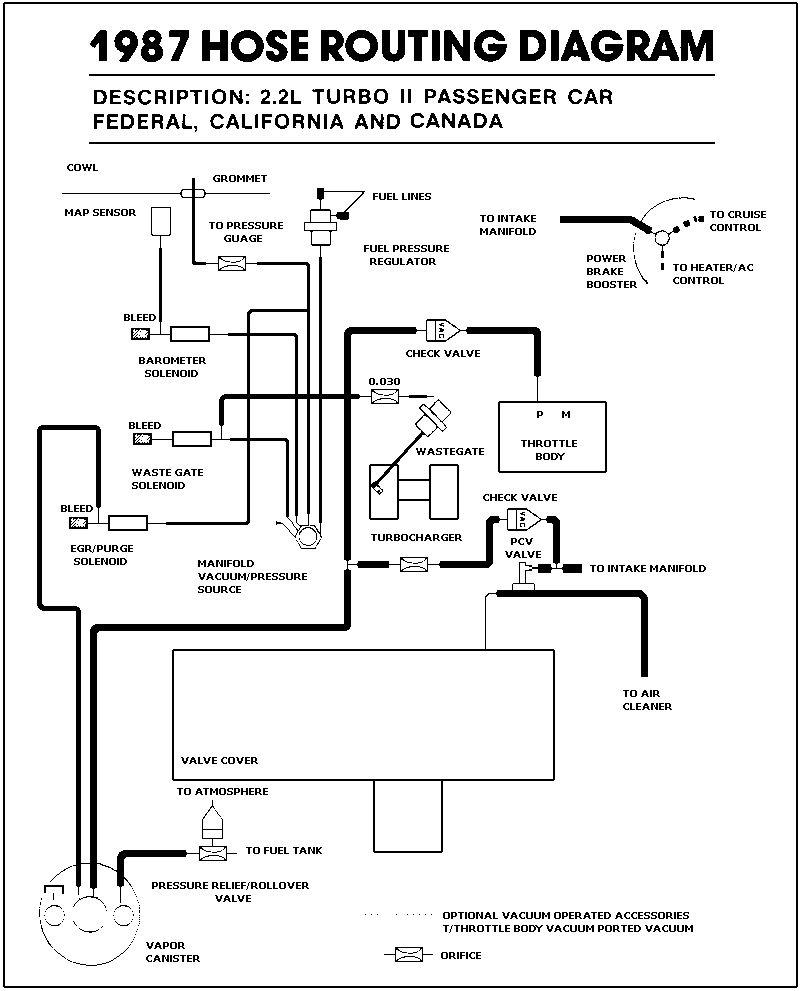

Vacuum Plumbing and SolenoidsThe vacuum harnesses are not available assembled from Chrysler or Shelby, which means you must either have to plumb your own (see diagrams) or get one off a junker. Without much modification, an '88 Turbo I or II harness will fit the bill.

Electronics/WiringDave began with stock 1987 electronics as a starting point (in the red car), with the only modification being a custom PROM chip in the logic module (behind the passenger side kick panel.) On the second go-around (the black beast) Dave updated with a 1989-vintage SMEC (Single Module Engine Controller), which incorporates the power and logic modules into one underhood unit. Dave's version bristles with custom electronics, including dial-the-boost and dial-the-advance capabilities.

In reality, it's the general unavailability of this custom software that prevents you and me from building clones of these cars. Perhaps, somewhere out there, there is someone with the knowledge, time, and ambition to make custom Chrysler chips on a regular basis. We'd like to hear from him.

The actual wiring harness on the red car is basically a stock Shelby GLH-S item. If you don't mind spending the money, just order one up and plug it in. Naturally, the black car features a hand-crafted wiring assembly.

ChassisThe chassis of Dyno Dave's ride is, remarkably, almost 100% stock. The only changes are stiffer Mopar Performance strut bushings (to cure the wheel hop) and a change to KYB gas dampeners.

One chronic problem is achieving hookup in a FWD car is the fact that, under acceleration, the weight will naturally tend to transfer to the rear wheels, just as it would in a RWD car. Unfortunately, as undesirable as this effect is, it carries with it a second drawback that is, fortunately, a bit easier to deal with.

Any strut-type suspension, no matter how well designed, will carry with it some degree of camber change during wheel travel. As the weight transfers rearward, the front of the car will, of course, rise due to the reduced loading. This will, then, affect the camber, and therefore, the effective tire patch making contact with the strip.

The fix? Simple. Video tape the car at launch, to determine the exact amount of rise on the front end. Now, jack up the car this amount and set the camber at zero. Of course, don't expect great tire wear and/or handling with the suspension set this way, but it will help the car to achieve significantly lower ETs.

Another avenue, and one that hasn't yet been explored by Dave, is that of fiddling with the rear suspension, principally by increasing the ride height to reduce the weight transfer.

All of these drag-only mods were, of course, considered a no-no for our One-Lap car (the black one), which had to handle as well as it launched. As the events turned out, this was even more important than we had suspected.

| Key Engine Parts | |||

| Part | Service Part no. | Description | |

| Valve Spring 8 reqrd. | P4286540 | MP Performance | |

| Cylinder head | P4529353 | MP Performance | |

| Turbo II short block assy. | 4343875 | ||

| Head gasket | 4448302 | ||

| Hose & intercooler to T/body | 5277054 | modified | |

| Air Cleaner | |||

| Cover | 4324156 | modified | |

| Housing | 4458025 | ||

| Bracket, a/clnr mounting | 4419953 | GLHS only | |

| Hose - air cleaner to turbo | 4306102 | modified | |

| Throttle body | 4307615 | V6 minivan | |

| Throttle cable | 4288197 | same as TII Daytona | |

| Bracket, cable mounting | 4288199 | same as TII Daytona | |

| Motor, AIS | 4467002 | same as TII Daytona | |

| Potentiometer, throttle | 5226924 | same as TII Daytona | |

| Stud, t/body attch. 2 reqrd. | 6100737 | same as TII Daytona | |

| Nut, t/body attaching 2 reqrd. | 6100050 | same as TII Daytona | |

| Fuel rail | 4418088 | 87 TII Daytona only | |

The red car used 15x6.5" cast wheels (made in England) which were stock on top-of-the-line Daytonas for many years. These are OK for occasional street use, but, for out 8500-mile 'Lap, Dave considered the running clearance to be marginal at best and inadequate at worst. Thus, the Black beast was shod with 15x6.0s, pirated from a late-model Shadow, and refinished in black.

Again due to clearance problems, the tires are no larger than P205/50R15s, with the only experimenting being in tire brand and tread compound. Dave has used everything from the stock-type Goodyear Gatorbacks, to Yokohamas, Hoosier autocrossers, and Michelin rally tires. His best efforts at the drags have so far been on the Michelins.

ConclusionAssuming you already own a GLH Turbo, you're halfway home. If not, clean used examples are now bringing less than $2,500. You are really just as well off with a well-worn piece, though, as you will be replacing much of the engine and drivetrain package. We recently saw an '85 with a spent clutch and blown head gasket change hands for $750. The stuff is starting to get realistic.

One way to get around the unavailability of the chip is to use an aftermarket fuel-enrichment device. One unit we've seen, and expect to test in the near future, is called the Turbo-Group Fueler (Miller-Woods, Inc. [405] 239-7959). This slick gadget includes its own add-on computer, a fifth injector nozzle (installed downstream of the turbine outlet), and programming simple enough for us couch-potato channel-zapper types. This gizmo could obviate the need for the unavailable chip, and also allow the use of the original injectors, saving mucho dinero in the process.

If you are lucky enough to find a junkyard with a Turbo II car that's not too heavily damaged, you can probably score 75% of what you need for a reasonable price. Otherwise, you'll have to go the "new" route, which ain't cheap. As usual, the old adage applies: if you wanna play ya gotta pay. Look at it this way: you'll make some of it back in gasoline and win the rest. With a best ET of 12.9 at almost 109, winning's a cinch, and, with a 60-foot ET of 2.12, there's easily another half-second still to be gained in making the beast hook up. Look out!

Dave allows that the new Lotus-head 2.2 as used in the Spirit R/T could be tweaked to outperform his "stock" mill. The biggest problem with the 4-valve motor is the fact that the crossflow-head's plumbing setup prevents installation in the dwarf-like L-body. The lightest vehicle that would accept the R/T mill would probably be the P-car (Shadow/Sundance). Then again, there's the cost factor, and the obvious "race" appearance of the motor, just the opposite of Dave's sleeper locomotive.

Then, of course, there's Detroit's "NIH" syndrome (Not Invented Here). Like, if we didn't design it, we don't want it, bad or good. In truth, Chrysler has historically been more open-minded to outside inventions than the other of the Big 3 automakers. Case in point: the incredible planetary gear set used in virtually all TorqueFlite was designed "elsewhere" (by a private inventor.) Chrysler clearly had the foresight to recognize a good thing when they saw it.

In this case, though, for now it's MoParts or NoParts!

The story is reprinted from MOPAR Action Magazine June 1991, Vol3, Num1 and MOPAR Action Magazine Tech Special #4 with the permission of Rick Ehrenberg. This is the basic story of how the MP Super 60 kit came to life!

Shelby Registry

Shelby Registry